Ke Kaʻina Hana Hoʻomaʻemaʻe Aiila: Hoʻoheheʻe Wai

Hōʻike huahana

ʻO ke kaʻina hana degumming i loko o ka mea kanu hoʻomaʻemaʻe aila ʻo ia ka wehe ʻana i nā haumia gum i loko o ka aila maʻemaʻe ma ke ʻano kino a i ʻole kemika, a ʻo ia ka pae mua o ka hoʻomaʻemaʻe ʻaila / hoʻomaʻemaʻe. Ma hope o ke kaomi ʻana a me ka wehe ʻana i ka mea hoʻoheheʻe mai nā hua aila, ʻo ka ʻaila ʻaila ka nui o nā triglycerides a me ka liʻiliʻi ʻole triglyceride. ʻO ka hui non-triglyceride me nā phospholipids, nā proteins, phlegmatic a me ke kō e hana me nā triglycerides e hana i ka colloid, i kapa ʻia ʻo nā haumia gum.

ʻAʻole pili wale nā mea ʻino i ke kūpaʻa o ka ʻaila akā pili pū kekahi i ka hopena o ka hoʻomaʻemaʻe ʻaila a me ka hana hohonu. No ka laʻana, he mea maʻalahi ka aila non-degummed e hana i ka aila emulsified i loko o ke kaʻina hoʻomaʻemaʻe alkaline, pēlā e hoʻonui ai i ka paʻakikī o ka hana, ka hoʻomaʻemaʻe ʻana i ka aila, a me ka hoʻohana ʻana i nā mea kōkua; i ke kaʻina hana decolorization, ka aila non-degummed e hoʻonui i ka hoʻohana ʻana i ka adsorbent a hoʻemi i ka pono discoloring. No laila, pono ka wehe ʻana i ke kāʻei e like me ke kaʻina mua o ka hoʻomaʻemaʻe ʻaila ma mua o ka deacidification aila, decolorization aila, a me ka deodorization aila.

ʻO nā ʻano kikoʻī o ka degumming ʻo ia ka hydrated degumming (water degumming), acid refining degumming, alkali refining method, adsorption method, electropolymerization and thermal polymerization method. Ma ke kaʻina hoʻomaʻemaʻe aila ʻai, ʻo ke ʻano maʻamau i hoʻohana ʻia ʻo ia ka hydrated degumming, hiki ke unuhi i nā phospholipids hydratable a me kekahi mau phospholipids non-hydrate, aʻo ke koena non-hydrate phospholipids pono e wehe ʻia e ka acid refining degumming.

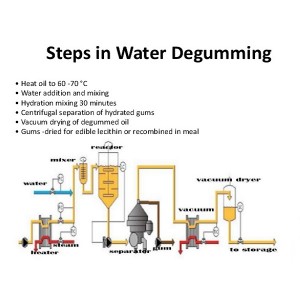

1. Ka loina hana o ka hydrated degumming (water degumming)

Aia i loko o ka aila ʻaila mai ke kaʻina hoʻoheheʻe ʻana i ka wai nā mea hiki ke hoʻoheheʻe ʻia i ka wai, ka mea nui i loko o nā phospholipids, pono e hoʻoneʻe ʻia mai ka ʻaila e hiki ai i ka ua liʻiliʻi a me ka hoʻopaʻa ʻana i ka wā o ka lawe ʻana i ka aila a me ka mālama lōʻihi. He ʻano hydrophilic ke ʻano o nā mea ʻino e like me ka phospholipids. ʻO ka mea mua, hiki iā ʻoe ke hoʻoulu a hoʻohui i kahi nui o ka wai wela a i ʻole electrolyte aqueous solution e like me ka paʻakai & phosphoric acid i ka ʻaila ʻaila wela. Ma hope o kekahi manawa hoʻololi, e hoʻokuʻu ʻia nā haumia gum, hoʻemi ʻia a wehe ʻia mai ka ʻaila. I ke kaʻina hana degumming hydrated, ʻo nā mea haumia he phospholipid, a me kekahi mau protein, glyceryl diglyceride, a me mucilage. ʻO ka mea hou aʻe, hiki ke hana ʻia nā ʻōpala i unuhi ʻia i lecithin no ka meaʻai, hānai holoholona a no ka hoʻohana ʻenehana.

2. ʻO ke kaʻina hana o ka hoʻoheheʻe wai (wai degumming)

ʻO ke kaʻina hana hoʻoheheʻe wai ʻo ia ka hoʻohui ʻana i ka wai i ka ʻaila maʻemaʻe, hoʻomaʻemaʻe i nā ʻāpana hiki ke hoʻoheheʻe ʻia i ka wai, a laila wehe i ka hapa nui o lākou ma o ka hoʻokaʻawale centrifugal. ʻO ka māhele māmā ma hope o ka hoʻokaʻawale centrifugal ʻo ia ka ʻaila degummed crude, a ʻo ka māhele kaumaha ma hope o ka hoʻokaʻawale centrifugal he hui pū ʻana o ka wai, nā ʻāpana wai a me ka ʻaila i hoʻopaʻa ʻia, i kapa ʻia ʻo "gums". Hoʻomaloʻo ʻia ka ʻaila degummed ma mua o ka hoʻouna ʻia ʻana i kahi waiho. Hoʻopi hou ʻia ka ʻāʻī ma luna o ka ʻai.

I loko o ka mea kanu hoʻomaʻemaʻe aila, hiki ke hoʻohana pū ʻia ka mīkini degumming hydrated me ka mīkini deacidification aila, ka mīkini decolorization, a me ka mīkini deodorizing, a ʻo kēia mau mīkini ke ʻano o ka laina hana hoʻomaʻemaʻe aila. Hoʻokaʻawale ʻia ka laina hoʻomaʻemaʻe i ke ʻano intermittent, semi-continuous type, a me ke ʻano hoʻomau piha. Hiki i ka mea kūʻai ke koho i ke ʻano e like me kā lākou mana hana e pono ai: ʻo ka hale hana me ka mana hana o 1-10t i kēlā me kēia lā e kūpono no ka hoʻohana ʻana i nā mea ʻano intermittent, 20-50t i kēlā me kēia lā hale hana kūpono no ka hoʻohana ʻana i nā mea hana semi-continuous type, e hana ana. ʻoi aku ma mua o 50t i kēlā me kēia lā kūpono no ka hoʻohana ʻana i nā lako ʻano hoʻomau. ʻO ke ʻano maʻamau i hoʻohana ʻia ʻo ia ka intermittent hydrated degumming production line.

ʻĀpana ʻenehana

ʻO nā kumu nui o ka hydrated degumming (wai degumming)

3.1 Ka nui o ka wai i hoʻohui ʻia

(1) Ka hopena o ka wai i hoʻohui ʻia i ka flocculation: Hiki i ka nui o ka wai kūpono ke hana i kahi hale liposome multi-layer paʻa. ʻAʻole lawa ka wai e alakaʻi i ka hydration incomplete a me ka flocculation colloidal maikaʻi ʻole; ʻO ka wai nui e hana i ka wai-ʻaila emulsification, he mea paʻakikī ke hoʻokaʻawale i nā haumia mai ka ʻaila.

(2) ʻO ka pilina ma waena o ka maʻiʻo wai i hoʻohui ʻia (W) a me ka maʻiʻo glum (G) i ka wela hana ʻokoʻa:

| haʻahaʻa wela hydration (20 ~ 30 ℃) | W=(0.5~1)G |

| ka hoʻoheheʻe ʻia o ka mahana wela (60 ~ 65 ℃) | W=(2~3)G |

| kiʻekiʻe wela hydration (85 ~ 95 ℃) | W=(3~3.5)G |

(3) Ho'āʻo laʻana: Hiki ke hoʻoholo ʻia ka nui kūpono o ka wai i hoʻohui ʻia ma o ka hoʻāʻo laʻana.

3.2 Hana wela

ʻO ka mahana hana e pili ana i ka mahana koʻikoʻi (no ka flocculation maikaʻi, hiki ke piʻi iki ka mahana o ka hana ma mua o ka wela koʻikoʻi). A e hoʻopili ka mahana hana i ka nui o ka wai i hoʻohui ʻia ke kiʻekiʻe ka mahana, nui ka nui o ka wai, inā ʻaʻole, liʻiliʻi.

3.3 Ka ikaika o ka hui ʻana o ka hydration a me ka manawa pane

(1) Hoʻomaʻemaʻe like ʻole: He ʻano like ʻole ka hoʻoheheʻe ʻana o ka gum i ka pilina pili. I mea e hana ai i kahi mokuʻāina emulsion aila-wai paʻa, hiki i ka hui ʻana o ka mīkini ke hoʻopuehu piha i nā droplets, pono e hoʻoikaika ʻia ka hui ʻana o ka mīkini ʻoi aku ka nui o ka wai i hoʻohui ʻia a he haʻahaʻa ka mahana.

(2) Intensityof hydration mixing: I ka hui ʻana i ka ʻaila me ka wai, ʻo ka wikiwiki o ka hoʻoulu ʻana he 60 r / min. I ka manawa o ka hana ʻana o ka flocculation, ʻo ka wikiwiki o ka hoʻoulu ʻana he 30 r / min. ʻO ka manawa pane o ka hui ʻana o ka hydration ma kahi o 30 mau minuke.

3.4 Electrolytes

(1) Nā ʻano like ʻole o nā electrolytes: Paʻakai, alum, sodium silicate, phosphoric acid, citric acid a dilute sodium hydroxide solution.

(2) Ka hana nui o ka electrolyte:

a. Hiki i nā electrolytes ke hoʻokaʻawale i kekahi hoʻoili uila o nā ʻāpana colloidal a hoʻoikaika i nā ʻāpana colloidal i sedimentate.

b. No ka hoʻololi ʻana i nā phospholipid non-hydrated i nā phospholipid hydrated.

c. Alum: kōkua flocculant. Hiki i ka Alum ke komo i nā puaʻa i loko o ka ʻaila.

d. E chelate me nā ion metala a wehe iā lākou.

e. No ka hoʻoikaika ʻana i ka flocculation colloidal kokoke a hōʻemi i ka ʻaila ʻaila o nā flocs.

3.5 Nā kumu ʻē aʻe

(1) Kaulike o ka aila: Ma mua o ka hydration, pono e hoʻoulu ʻia ka ʻaila ʻaila i hiki ke puʻunaue like ʻia ka colloid.

(2) ka mahana o ka wai i hoʻohui ʻia: I ka wā e hoʻomaʻemaʻe ʻia ai, pono e like ka mahana o ka hoʻohui ʻana i ka wai a i ʻole ke kiʻekiʻe iki ma mua o ka mahana o ka aila.

(3) Hoʻohui i ka maikaʻi o ka wai

(4) Paʻa hana

ʻO ka mea maʻamau, ua hoʻoholo ʻia nā ʻāpana ʻenehana o ke kaʻina degumming e like me ka maikaʻi o ka ʻaila, a ʻokoʻa nā ʻāpana o nā ʻaila like ʻole i ka hana degumming. Inā makemake ʻoe i ka hoʻomaʻemaʻe ʻaila, e ʻoluʻolu e kelepona mai iā mākou me kāu mau nīnau a manaʻo paha. E hoʻonohonoho mākou i kā mākou ʻenehana loea e hana i kahi laina aila kūpono i hoʻolako ʻia me nā lako hoʻomaʻemaʻe aila kūpono no ʻoe.